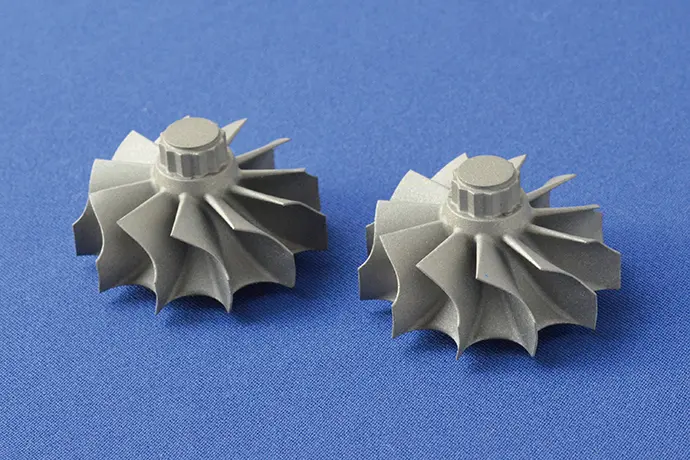

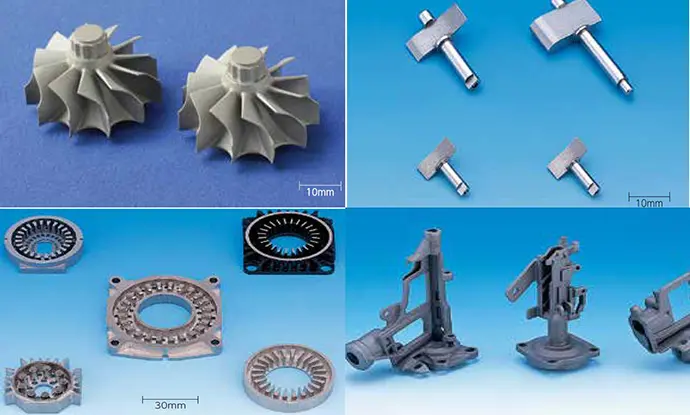

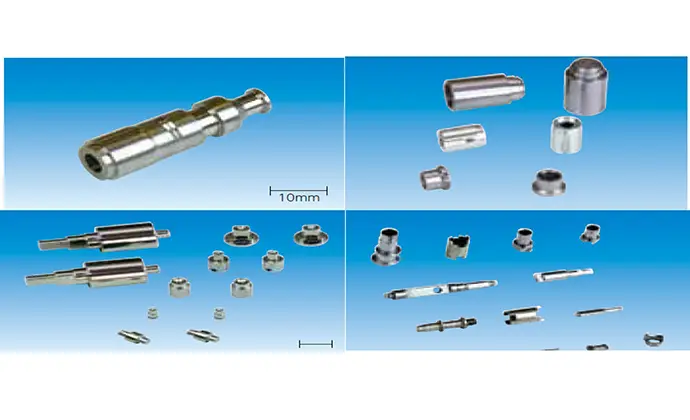

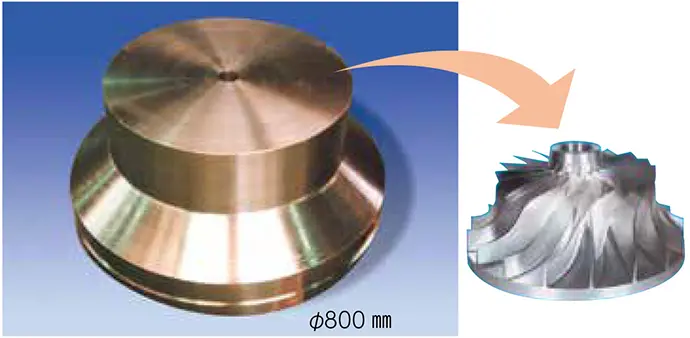

Formed & Fabricated Products

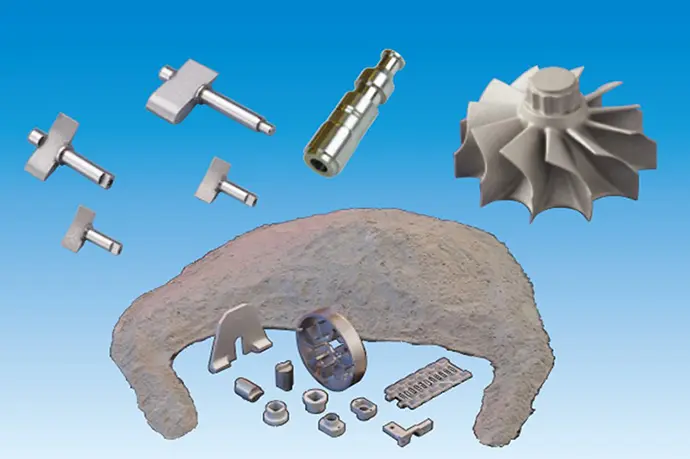

This business field creates added value from materials. We employ special alloy powders, casting and machining technologies to manufacture formed and fabricated products with applications across a wide range of industries.

It is used in various applications such as automobiles, ships, electrical and electronic equipment, industrial equipment, agricultural machinery, etc. The production bases are Hirota Factory in Aizuwakamatsu City, Fukushima Prefecture, and MSM-Thailand in Chonburi Province, Thailand. At Hirota Factory, all power used will be 100% renewable energy from April 2023, promoting decarbonization.

Products

Uses

Contact for Formed & Fabricated Products

Fanctional Parts Sales Department