Special materials and machined products

Our company is capable of small-lot melting. We can deliver a wide variety of steel ingots, from 10 tons/CH to 16 tons/CH, in a short lead time according to your required amount.

The steel ingots manufactured by our company are transported to forging manufacturers, where they undergo forging to achieve the required material properties, and are shaped as closely as possible to the final form.

In the secondary melting (ESR) process, we are able to manufacture high-purity steel that requires high mechanical properties by improving component segregation and structural heterogeneity.

Products

Special materials and machined products

- Features

By employing external refining and vacuum degassing, we have primary melting equipment that can reduce non-metallic inclusions and gas components, and secondary melting equipment that can provide materials that meet strict requirements for gases and inclusions by utilizing the electroslag remelting process.

- Uses

General forged products (Retainer Rings, Piston Rods)

Marine parts materials (TW material, Conrod material, Crankshaft material)

Glass roll, main shaft for pulverizer, ultra-high pressure parts material

Examples of Possible Steel Types and Ingot Shapes

| Carbon Steel | S20C~S55C etc. |

|---|---|

| ASTM Materials | ASTM SA723 |

| Hot Work Tool Steel | SKT4,SKD61 |

| Low Alloy Steel | SCM,SNCM etc. |

| AISI Materials | AISI4335 |

| Stainless Steel | Martensitic Series: SUS403,SUS410,SUS420J2 Austenitic Series: SUS304,SUS310S Precipitation Hardening Type: SUS630 |

| Roll Materials | 3%Cr,4%Cr,5%Cr,13%Cr |

| Heat Resistant Steel | SUH660 |

Please feel free to consult us.

Primary Melting (LF) Ingot

Secondary Melting (LF+ESR) Ingot

Applicable Standards

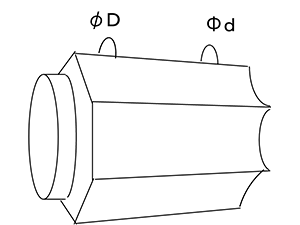

| Designation | Case Size | Weight (T) | ||

|---|---|---|---|---|

| Bot Diameter | Top Diameter | Length | J(12%) | |

| 4T | 590 | 719 | 1620 | 3.0~4.1 |

| 6T | 698 | 858 | 1608 | 3.7~5.7 |

| 8T | 769 | 945 | 1767 | 5.2~7.5 |

| 10T | 849 | 1035 | 1852 | 7.0~9.5 |

| 13T | 952 | 1145 | 1936 | 8.6~12.5 |

| 16T | 1020 | 1228 | 2069 | 11.5~15.2 |

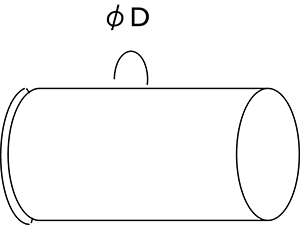

| Designation | Case Size | Weight (T) | ||

|---|---|---|---|---|

| Bot Diameter | Top Diameter | Length | J(12%) | |

| φ570 | 590 | 556 | 2750 | 2.0~3.9 |

| φ660 | 698 | 646 | 2750 | 3.5~4.5 |

| φ820 | 769 | 798 | 4275 | 4.9~13.3 |

| φ870 | 849 | 849 | 4275 | 9.3~17.0 |

| φ980 | 952 | 954 | 4275 | 12.0~17.0 |

Technology

Mitsubishi Steel's Processing Technology

Our company has a 15T electric furnace and refining furnace (LF), and vacuum degassing equipment, which allows us to manufacture steel ingots that have reduced non-metallic inclusions and gas components. We are also certified by various ship classes (NK, LR, ABS).

Furthermore, we own ESR (Electro Slag Remelting) equipment, which allows us to manufacture steel ingots that have improved purity and reduced component segregation by remelting the material.

These facilities enable us to manufacture low alloy steel to high alloy steel such as SUS materials, and even high purity steel, which has received high praise from many users.

Integrated Production from Materials to Processing

While it is possible to deliver the steel ingots we manufacture directly to our customers, we also offer services such as forging, machining, and heat treatment of the ingots, allowing us to deliver finished products. If we receive drawings (delivery diagrams) from our customers, we can consider processing schemes (drawings) for each process, heat treatment schemes, forging schemes, etc., and calculate the required weight of the steel ingots. We also offer various processing services, including heat treatment, lathe work, milling, and more.

Producing Turbine Wheels from Materials

Using our 15T electric furnace, refining furnace (LF), and degassing equipment, we manufacture steel ingots, perform forging, machining, heat treatment, and inspection. This product is used in the turbochargers of marine diesel engines, so we confirm mechanical properties and perform non-destructive inspections under the supervision of various ship class inspectors.

Contact for Formed & Fabricated Products

Fanctional Parts Sales Department