Precision Castings

Since our founding, as a representative Japanese foundry and forging steel manufacturer, we have been manufacturing a wide range of components for the heart of modern key industries. Currently, at Hirota Works and MSM(THAILAND)CO., LTD., we manufacture cast and forged products mainly of iron, and cast and forged products of high-function special alloys used in a wide range of fields including automobiles, aviation and marine, energy, electronics, and more.

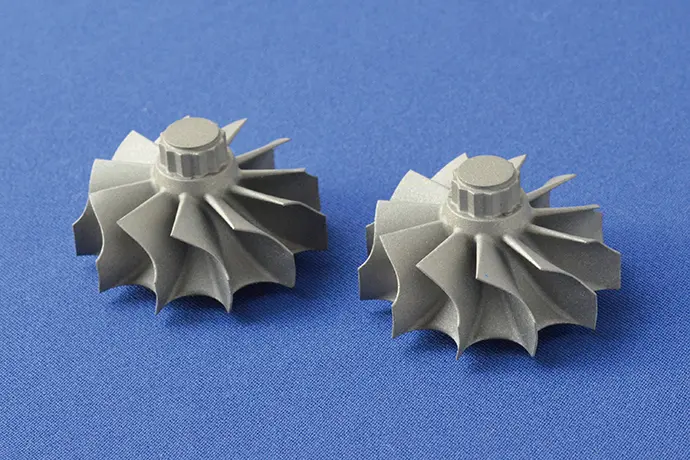

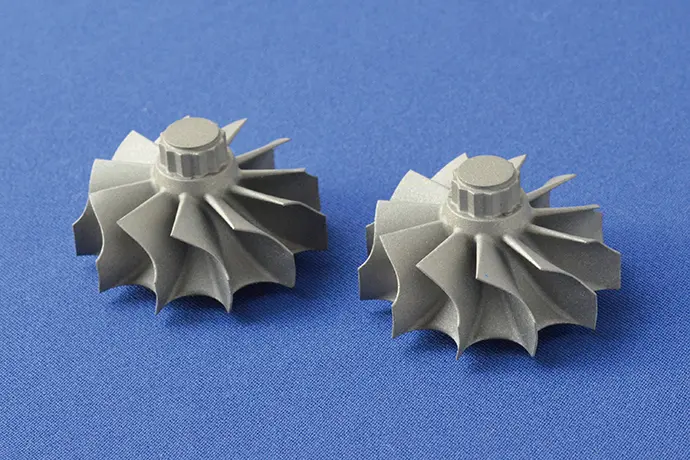

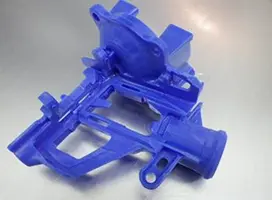

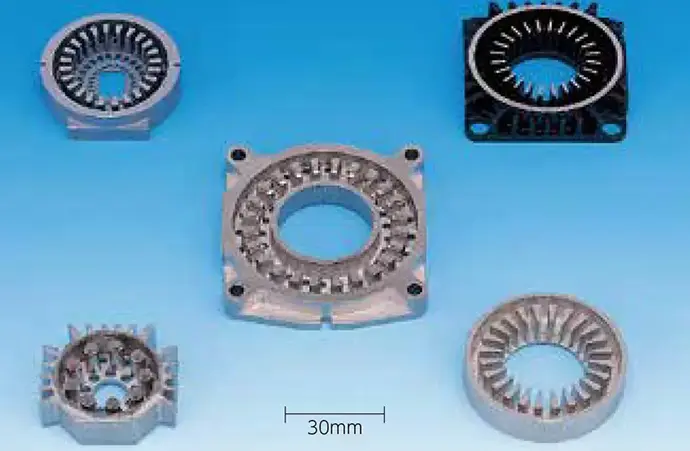

For lost wax products, we can manufacture complex, thin-walled shapes for small products ranging from 1g to about 20kg. We recommend lightening and integrating parts as a cost reduction proposal, utilizing our casting technology. In addition, by creating a prototype with a 3D printer, we can quickly provide a prototype to our customers. Moreover, complex shaped products can be quickly measured by a non-contact three-dimensional measuring machine. We can also handle special materials that require vacuum melting.

Products

Precision Castings

- Features

We have the following features due to our unique modeling and casting plans:

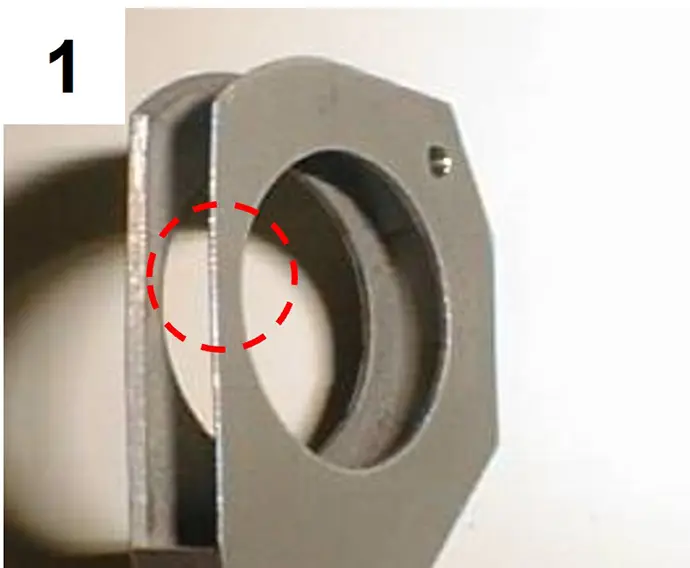

- 1Compatible with thin-walled shapes (minimum wall thickness 0.2mm)

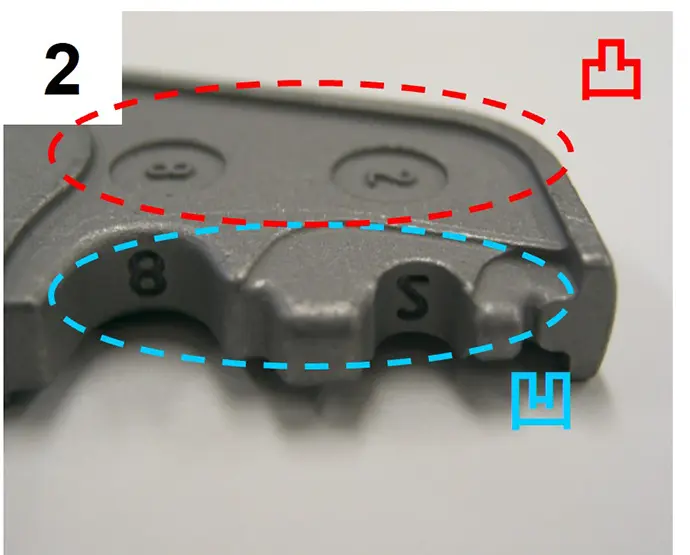

- 2Compatible with cast letters (convex 0.3mm or more, concave 0.2mm or more)

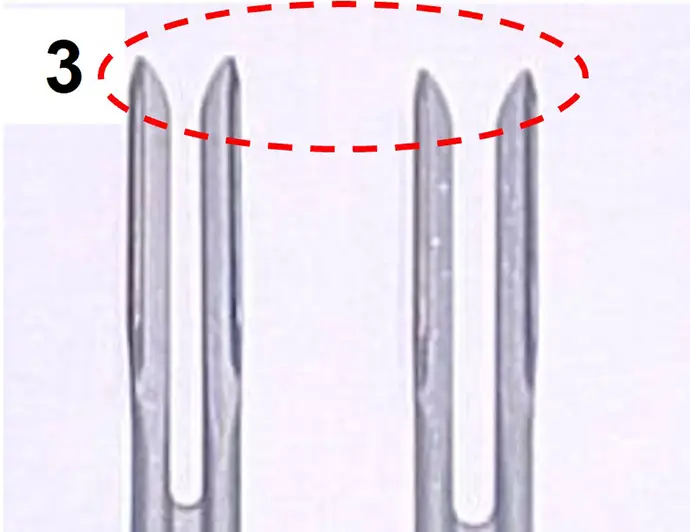

- 3Sharp edges (up to a minimum R0.3mm at the tip)

- 4Accommodates deep holes (through holes up to 3-5 times the diameter, non-through holes up to 1.5 times the diameter)

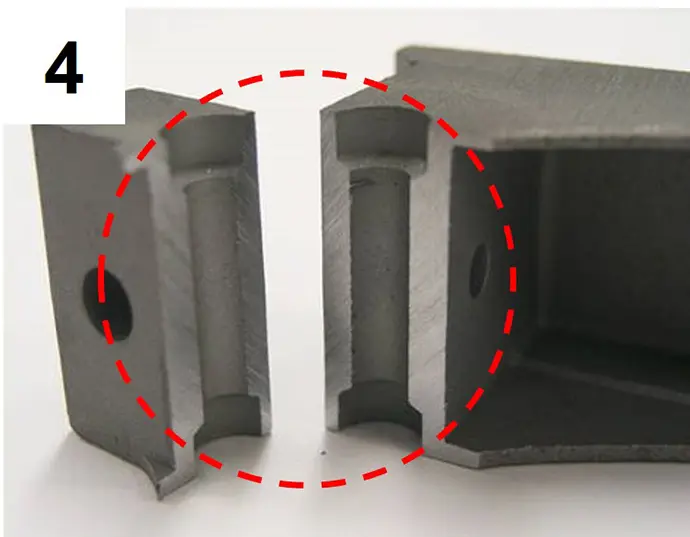

- 5Compatible with complex shapes (e.g., nailer parts)

We own various processing equipment and can handle secondary processing in-house.

- Uses

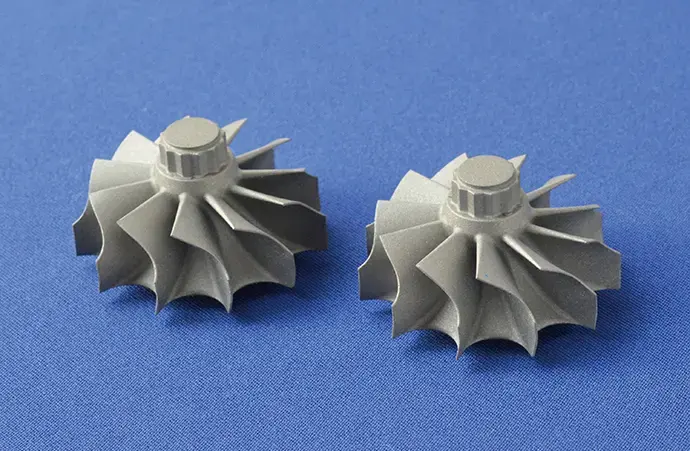

Turbocharger parts (nozzle vanes, turbine wheels, other peripheral parts)

Printer yokes

Nailer parts

Other various industrial parts

We own a dedicated factory for turbocharger turbine wheels.

We manufacture special material products and products requiring complex, thin-walled shapes in a consistent manner, using our automated moulding line and vacuum melting equipment.

Prototype support with 3D printer

By fabricating wax models with a 3D printer, no mold is needed, which can shorten the prototype delivery time.

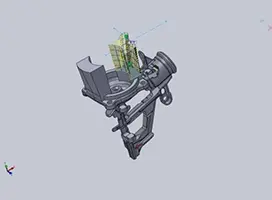

- 1Creation of 3D models (Simulation of solidification analysis using CAE analysis)

- 2Molding of WAX by 3D printer

- 3Creation of samples through the usual process of precision casting

- 4Evaluation of product shape by non-contact three-dimensional measuring machine

Compliance with international standards

We have obtained certification for ISO9001, ISO14001, and IATF16949.

Uses

We can mass-produce complex shapes using the lost wax process, and we can also handle a variety of materials, including difficult-to-cut materials.

Contact for Formed & Fabricated Products

Fanctional Parts Sales Department