Special Alloy Powders

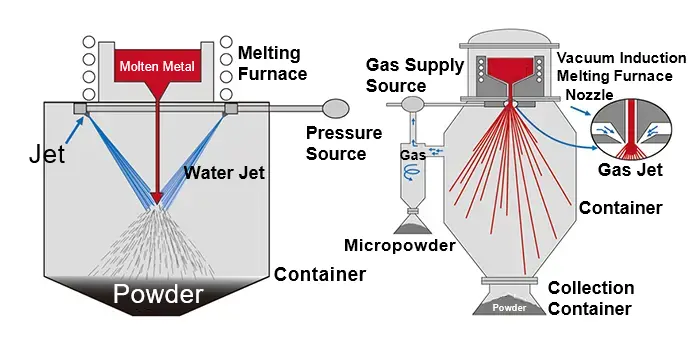

Our powders are produced using two methods, water atomization and gas atomization, to make special alloy powders. We respond to the demands of customers from various industries. The particle size can be manufactured from several μm to several hundred μm according to various requests. Furthermore, we actively provide technical support from the composition design to the analysis at the development stage, and small quantities can be handled on the prototype line.

Products

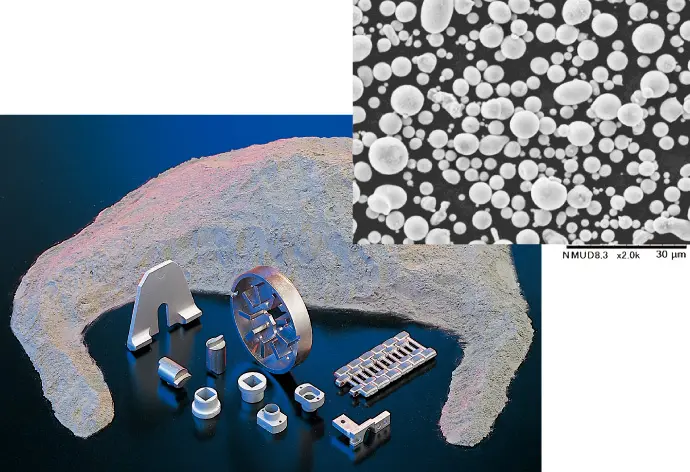

MIREX Powders

- Features

Compared to general water atomized powders, we produce low oxygen powders that excel in compressibility and moldability.

- Uses

Powder metallurgy (PM, HIP, CIP)

Thermal spraying, Welding

Filters

Various additives

Fine MIREX Powders

- Features

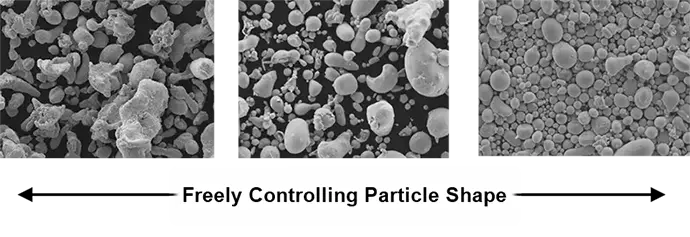

By controlling the particle shape (irregular to spherical) and particle size, we can manufacture powders with low to high TAP densities.

- Uses

Metal injection molding (MIM)

Electromagnetic shielding

Metal composite inductor

Paint

Various additives

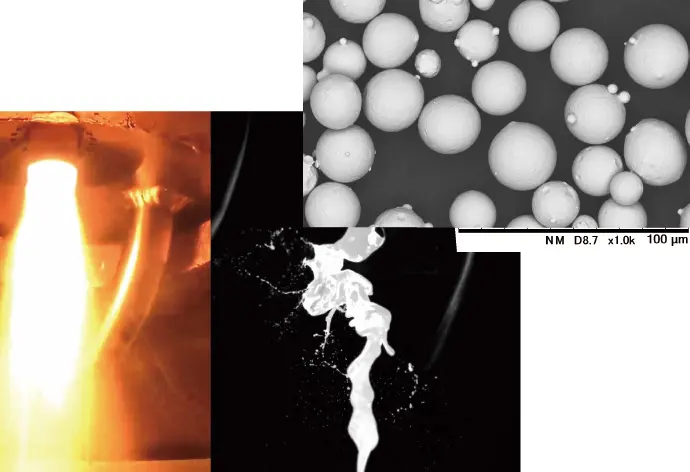

MIREX Gas Atomized Powders

- Features

We manufacture powders with low satellite, low oxygen, and high roundness. The particle size distribution can also be freely controlled. We can also handle small lots on the prototype line. Thanks to the anti-satellite system (*), a feature of our mass production equipment, we can produce powders with reduced satellites.

- *The anti-satellite system can suppress the retention of powder by returning the powder and separated spray gas back to the atomization tower after atomization.

- Uses

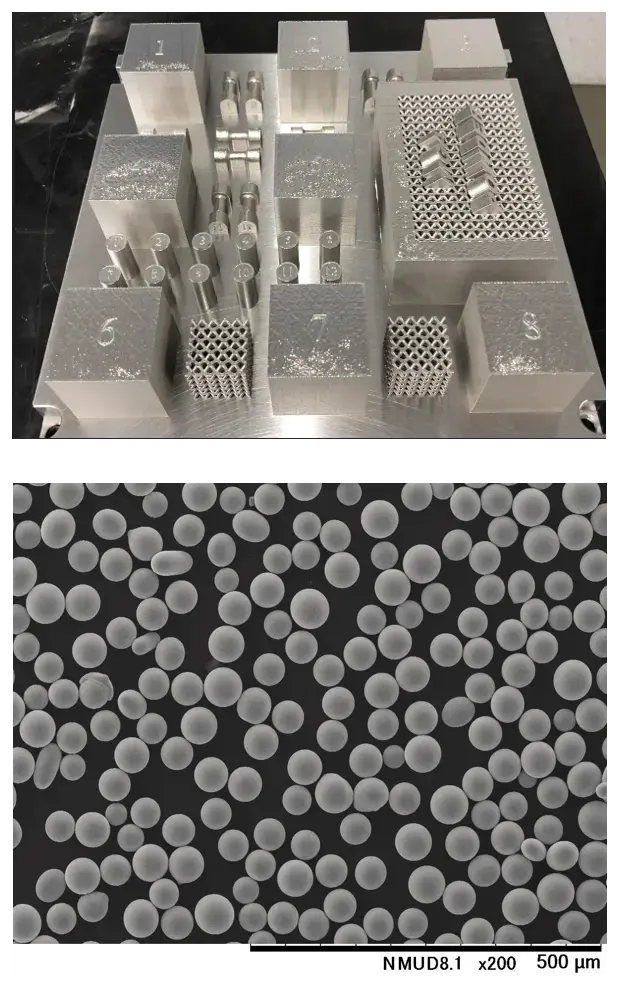

3D metal printer

Thermal spraying, welding

HIP

Electronic parts

Process Overview Diagram

Technology

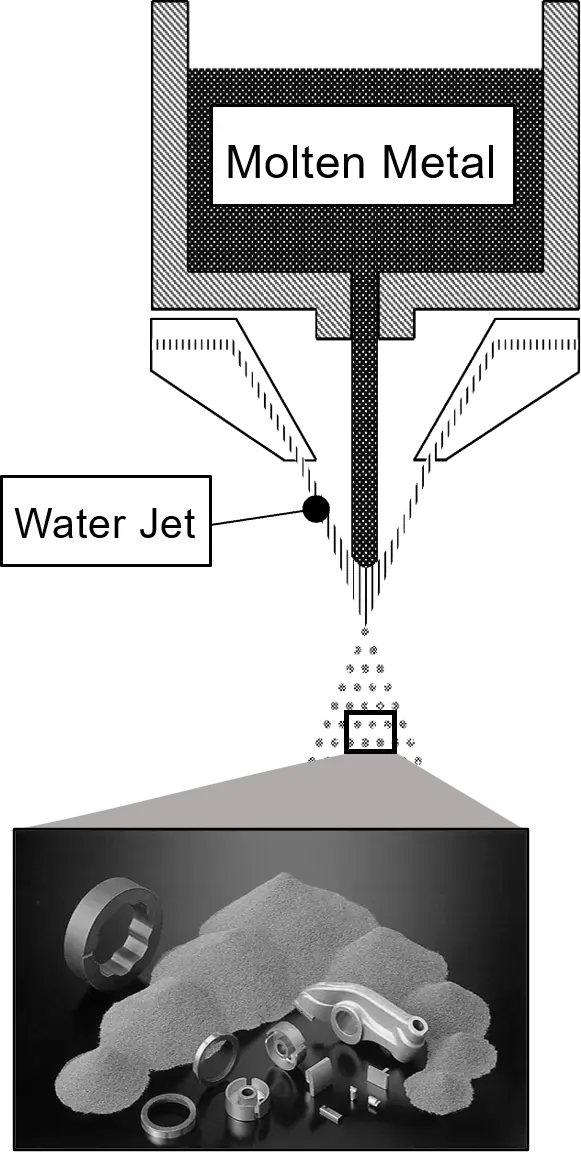

Mitsubishi Steel's Water Atomized Powder Leveraging Diverse Manufacturing Technologies

Mitsubishi Steel's metal powders are used in a variety of applications including powder metallurgy, MIM, inductors, and magnetic sheets, thanks to our advanced water atomization technology and our unique mass production annealing technology. According to customer requests, we manufacture and prototype to meet a wide range of needs, including particle size, powder shape, and composition (we have a prototype line that can handle small lots). Furthermore, since April 2023, we have been manufacturing metal powders using 100% CO2-free electricity, aiming for clean powder production considering environmental preservation.

Features

- Adjustment of particle size from several μ to several hundred μ

- Fine adjustment of various components

- High tap density

- Low oxygen

- Low residual magnetism

Started Mass Production of Gas Atomized Powder for 3D-P

In 2022, we introduced a gas atomization mass production device (maximum melting amount of 250kg/ch). Leveraging the know-how accumulated from development, we have started mass production of nickel-based and iron-based steel types. The anti-satellite system (*1), a feature of our mass production equipment, enables us to produce powders with reduced satellites.

We conduct mechanical property investigations on formed bodies, microstructure analyses, precipitate analyses, etc., by performing 3D laminated modeling with the L-PBF method using our powder, and we are also advancing tuning for use as 3D-P powder.

We manufacture and prototype to meet a wide range of needs, including particle size, powder shape, and composition, according to customer requests (we have a prototype line that can handle small lots). Furthermore, since April 2023, we have been manufacturing metal powders using 100% CO2-free electricity, aiming for clean powder production considering environmental preservation.

- *1The anti-satellite system can suppress the retention of powder by returning the powder and separated spray gas back to the atomization tower after atomization.

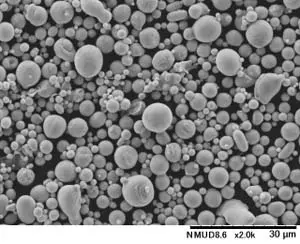

Trial Manufacturing Line of Water Atomizing for fine metal powder manufacturing was newly installed in Hirota Works

In October 2020, we newly installed a trial manufacturing line of water atomizing for fine metal powder and started its operation in Hirota Works (Aizu-Wakamatsu city, Fukushima prefecture), a domestic base of Formed & Fabricated Products Business.

In this trial manufacturing line, we conduct tests for the purpose of improvement of qualities and technologies of soft magnetic metal powder which is used for fine metal powder for MIM (metal injection molding) and inductors.

In the future, we will accumulate know-how on manufacturing the fine metal powder by water atomization method, try to improve quality characteristics and meet the needs of novel material development.

SEM Image (×2000)

Coping Standards

| Classification | Alloy Grades | Equivalent Materials | Chemical Composition | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | Ni | Cr | Mo | V | W | Co | Cu | Nb | Al | Fe | |||

| High Speed Steels | SKH51 | M2 | 0.85 | 0.3 | 0.2 | - | 4.2 | 5.0 | 2.0 | 6.0 | <1.0 | - | - | - | Bal. |

| SKH57 | - | 1.30 | 0.3 | 0.3 | - | 4.2 | 3.5 | 3.4 | 10.0 | 10.0 | - | - | - | Bal. | |

| Alloy Tool Steels | SKD61 | H13 | 0.40 | 1.0 | 0.4 | - | 5.0 | 1.3 | 1.0 | - | - | - | - | - | Bal. |

| SKD11 | D2 | 1.70 | 0.4 | 0.4 | - | 12.0 | 1.0 | 0.5 | - | - | - | - | - | Bal. | |

| Ferritic Stainless Steels | SUS410L | - | 0.03 | 1.0 | 0.2 | - | 12.5 | - | - | - | - | - | - | - | Bal. |

| SUS430L | - | 0.03 | 0.9 | 0.2 | - | 17.0 | - | - | - | - | - | - | - | Bal. | |

| Austensitic Stainless Steels | SUS304L | - | 0.03 | 0.9 | 0.2 | 10.0 | 19.0 | - | - | - | - | - | - | - | Bal. |

| SUS310S | - | 0.05 | 1.0 | 0.2 | 20.5 | 25.0 | - | - | - | - | - | - | - | Bal. | |

| SUS316L | 0.03 | 0.9 | 0.2 | 12.0 | 17.0 | 2.5 | - | - | - | - | - | - | Bal. | ||

| Marttensitic | SUS420J2 | - | 0.60 | 0.9 | 0.2 | - | 13.0 | - | - | - | - | - | - | - | Bal. |

| SUS440C | - | 1.00 | 1.0 | 0.3 | - | 17.0 | - | - | - | - | - | - | - | Bal. | |

| 440C-Nb | - | 1.30 | 1.0 | 0.3 | - | 17.0 | - | - | - | - | - | 3.0 | - | Bal. | |

| Precipitation Hardening Stainless Steels | 17-4PH | SUS630 | 0.07 | 0.8 | 0.2 | 4.0 | 16.5 | - | - | - | - | 4.0 | 0.3 | - | Bal. |

| Heat resistant steel | MGA-625 | - | 0.10 | 0.5 | 0.5 | Bal. | 22 | 9 | - | - | - | - | 3.6 | - | 5 |

| MGA-718 | - | 0.08 | 0.4 | 0.4 | 54 | 19 | 3.1 | - | - | - | - | 5.2 | 0.5 | - | |

| Super Alloys | Super Co400 | - | 0.05 | 2.6 | 0.1 | - | 8.5 | 29.0 | - | - | Bal. | - | - | - | 3.0 |

| F75 | - | 0.35 | 0.7 | - | 0.5 | 28.5 | 6.0 | - | - | Bal. | - | - | - | 1.5 | |

| Low Expansion Alloys | F15 | - | 0.02 | 0.2 | 0.2 | 29.0 | - | - | - | - | 17.0 | - | - | - | Bal. |

| Low Alloys Steels | SNCM439 | AISI4340 | 0.45 | 0.7 | 0.8 | 1.8 | 0.8 | 0.2 | - | - | - | - | - | - | - |

| SNC631 | - | 0.52 | 0.7 | 0.5 | 2.8 | 0.8 | - | - | - | - | - | - | - | - | |

| Soft Magnetic Powder | Fe-6.5%Si | - | 0.01 | 6.5 | - | - | - | - | - | - | - | - | - | - | Bal. |

| Fe-Si-Cr | - | 0.01 | ~6.5 | - | - | ~5.0 | - | - | - | - | - | - | - | Bal. | |

| Fe-13Si-1Cr | - | 0.01 | 13.5 | 0.2 | - | 1.1 | - | - | - | - | - | - | - | Bal. | |

| PB | Permalloy B | 0.01 | 0.4 | - | 49.0 | - | - | - | - | - | - | - | - | Bal. | |

| PC | Permalloy C | 0.01 | 0.1 | - | 78.0 | - | 5.0 | - | - | - | - | - | - | Bal. | |

| Fe-49%Co-2%V | - | 0.01 | 0.4 | - | - | - | - | 2.0 | - | 49.0 | - | - | - | Bal. | |

| Fe-50%Co | - | 0.01 | 0.1 | - | - | - | - | - | - | 50.0 | - | - | - | Bal. | |

| Fe-Si-Al | - | 0.01 | 9.5 | - | - | - | - | - | - | - | - | - | 5.5 | Bal. | |

- *We can also manufacture items not listed in the above table. Please feel free to inquire.

Contact for Formed & Fabricated Products

Fanctional Parts Sales Department