DX promotion

Mitsubishi Steel established the DX Promotion Office in 2021 as part of efforts to promote digital transformation (DX) throughout the organization. Beyond simply deploying IT to make business processes more efficient, DX seeks to leverage IT and other digital technologies to transform products, services, and business models and generate new value.

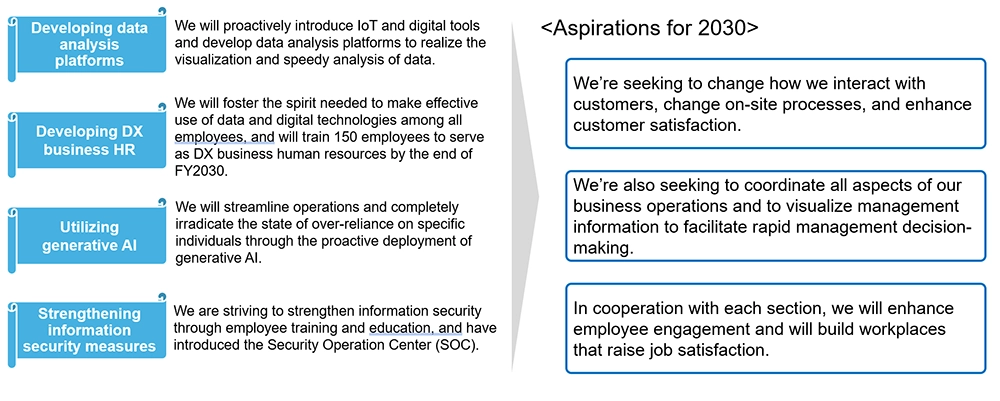

In an era of dramatic change in society and progressive advances in digitalization, Mitsubishi Steel positions DX promotion as an important management strategy. The DX Promotion Office has set the following goals under the ideal vision for 2030:

- 1To transform customer service and workplace processes, strengthen customer satisfaction, and grow sales and profits

- 2To enable swift management decision-making by linking operations throughout the organization and making management information visible

- 3To build rewarding workplaces by connecting individual sections, thereby strengthening employee engagement

In August 2023, our company was certified as a “DX Certified Business Operator” by the Ministry of Economy, Trade and Industry, and the certification was renewed in August 2025. The certification is valid until the end of July 2027.

- List of Certified Businesses under the DX Certification System

Basic DX policy

We will advance structural reforms supported by data and digital technologies.

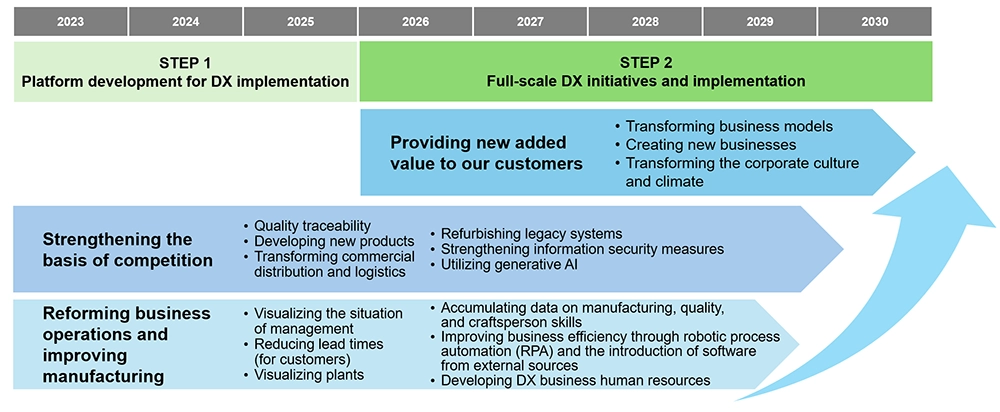

Road map

We’ve been determined to develop platforms for DX implementation throughout 2023 to 2025 to prepare for the full-scale DX initiatives and implementation planned from 2026 and beyond.

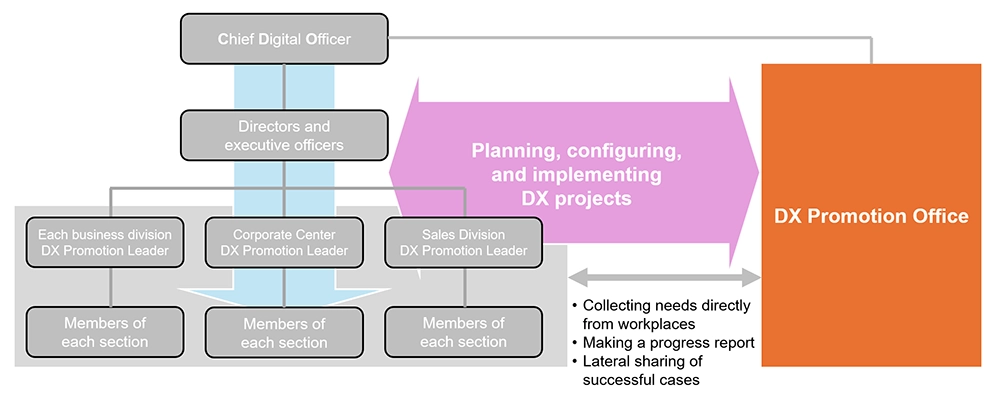

Organization for DX promotion

The DX Promotion Office was established under the Chief Digital Officer (CDO) to achieve corporate reforms based on a broad perspective that transcends the framework of business divisions. This Office is in charge of planning and configuring DX projects. We’ve assigned a DX promotion leader to each section and established an organizational structure that allows management to monitor the on-site progress of DX efforts and the precise and rapid communication of management perspectives to those stationed at work sites.

Future prospects and strategies

We plan to take four key initiatives to create new added value.

DX Cases

Without changing the configuration of the basic equipment (hardware), we have replaced the control system + software with general-purpose equipment under our own initiative.

- STEP.1: Digitization of skilled workers' techniques + Quantification of know-how + Labor reduction

- STEP.2: Data collection using the latest sensing equipment + Accumulation and analysis of know-how

- STEP.3: Quality and productivity improvement + Equipment failure prediction ⇒ Full automation, solving labor shortage

We will package this case study and promote its horizontal deployment to other business locations.

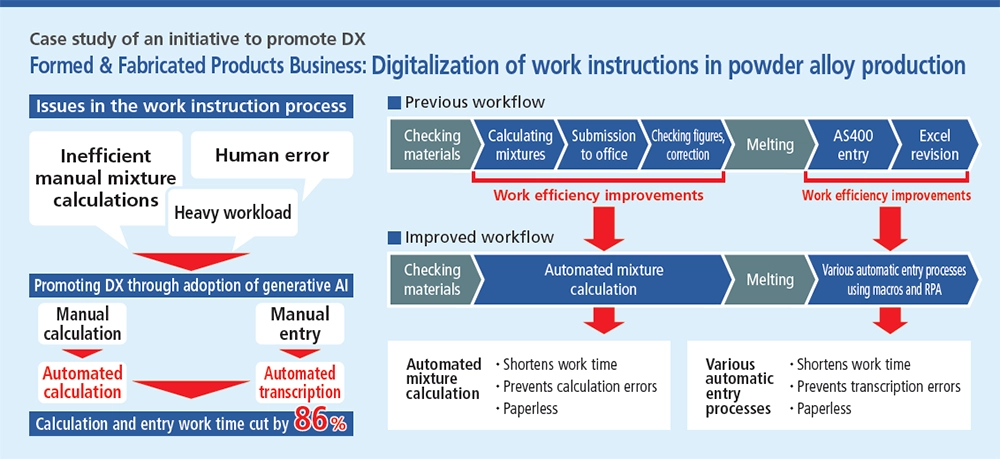

Digitalization of work instructions in powder alloy production