Non-heat treated steels

Non-heat treated steels is a type of steel that can achieve the required properties without undergoing quenching and tempering processes, and is left as it is after hot rolling or hot forging. This can lead to energy savings and simplification of processes.

Main Manufactured Steel Types

| Steel | Strength | Chemical Composition | Structure | Uses | |||

|---|---|---|---|---|---|---|---|

| C | Mn | Cr | V | ||||

| S40CV | ≧740MPa | 0.40 | 0.70~1.20 | 0.10~0.30 | 0.08~0.14 | Ferrite + Pearlite type | Hot forging |

| S43CV | 0.43 | ||||||

| S45CV | ≧780MPa | 0.45 | |||||

| S48CV | 0.48 | ||||||

| SMNV45 | ≧830MPa | 0.45 | 1.10~1.40 | ||||

| VMC15 | ≧740MPa | 0.15 | 1.70~2.00 | 0.30~0.50 | 0.10~0.30 | Bainite type | Hot forging |

| VMC25 | ≧880MPa | 0.25 | |||||

| VMC35 | 0.35 | ||||||

| SMT75 | ≧740MPa | 0.32~0.46 | 1.00~1.80 | 0.15~0.50 | 0.08~0.20 | Ferrite + Pearlite type | Direct cutting |

| SMT90 | ≧880MPa | ||||||

Uses

Construction Machinery: Piston Rod, Pin, Shaft

Truck: Conrod, Crankshaft, Knuckle, Front Axle

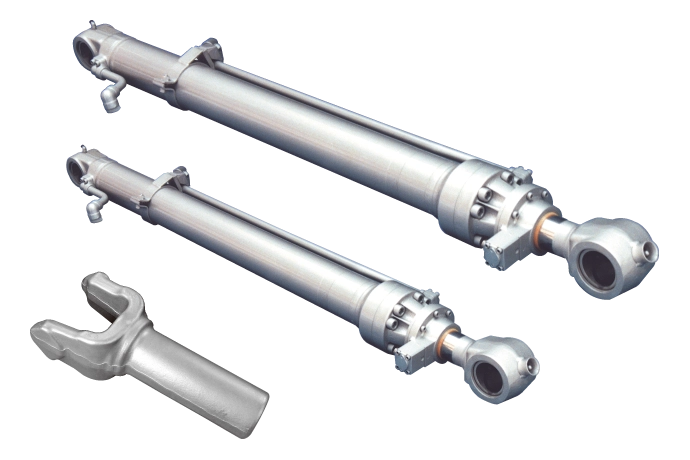

Non-heat treated steels Used in Construction Machinery Parts

It is used in hydraulic cylinders, yokes, and rod heads of construction machinery.

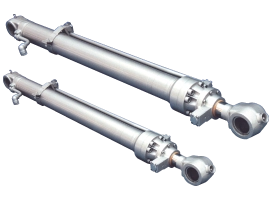

Non-heat treated steels Used in Trucks

It is used in critical components such as engines and undercarriages, and has gained high reliability.

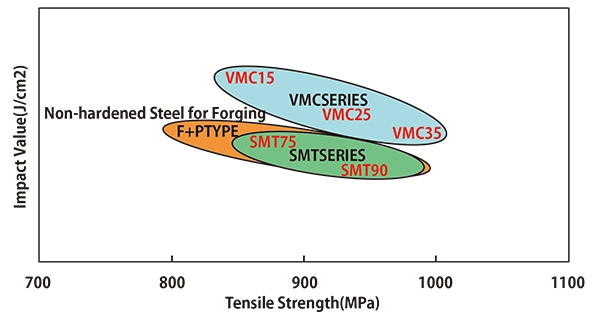

Characteristics (Toughness & Impact Value)

Contact for Special Steel Products

Steel Sales Department