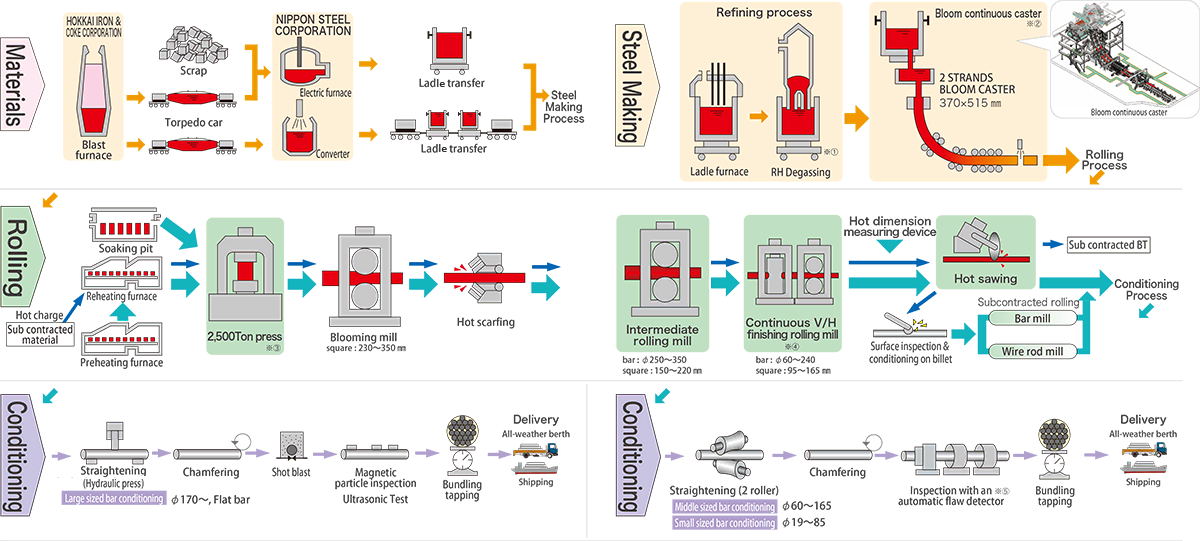

Manufacturing Process

Mitsubishi Steel Muroran Inc.

Mitsubishi Steel is a pioneer in the world to produce structural steels for automobile through LF (Ladle refining furnace) Degassing-Bloom continuous casting process and left mark on quality improvement. Now, Mitsubishi Muroran is trying higher quality and productivity improvement in addition to savi ng energy to produce earth environmental friendly special steels through compounding pig iron with scrap.

- Main Manufactured Steel Types

Special Steel Products(Structural Carbon Steels & Alloy Steels, Non-heat treated steels, Spring Steels, High Carbon Chromium Bearing Steels, Others)

- Manufacturing dimensions

Round Bar:φ19 ~ φ350mm (*φ19 ~ φ59mm Contract manufacturing)

square Bar:Square 80 ~ Square 350 (*Square 80 ~ Square 90 Contract manufacturing)

JATIM TAMAN STEEL

PT. JATIM TAMAN STEEL MFG. is an overseas base for the steel business of the Mitsubishi Steel Group, with full backup from Mitsubishi Steel to ensure superior quality. As the only integrated special steel manufacturer in Indonesia, we supply special steel round bars and flat steel, meeting the needs of our customers for local procurement.

- Main Manufactured Steel Types

Special Steel Products(Structural Carbon Steels & Alloy Steels, Spring Steels, Others)

- Billet Size

Square 160

- Manufacturing dimensions

Round Bar φ19 ~ φ90mm

Flat Bar Width 50 ~ 130mm *Thickness 5 ~ 45mm

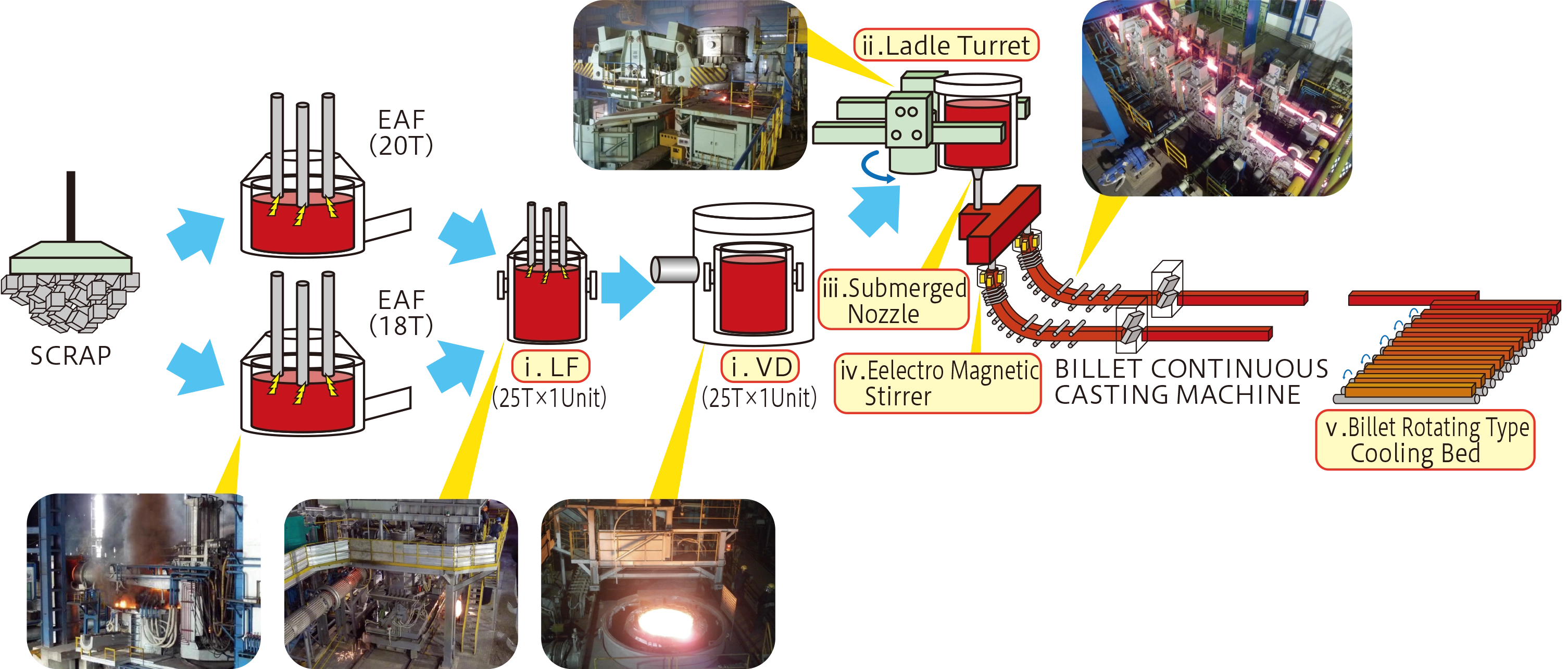

Steel Making Plant

- 1Rapid ladle exchange by ladle turret method

- 2Non-oxidation casting using air gap nozzle between ladle, tundish, and mold

- 3Reduction of center segregation and inclusions by electromagnetic stirring in the mold

- 4Reduction of billet bending by adopting billet rotating cooling bed

- Steel making capacity:

13.5 thousand tons/month (billet amount)

12.3 thousand tons/month (converted product amount)

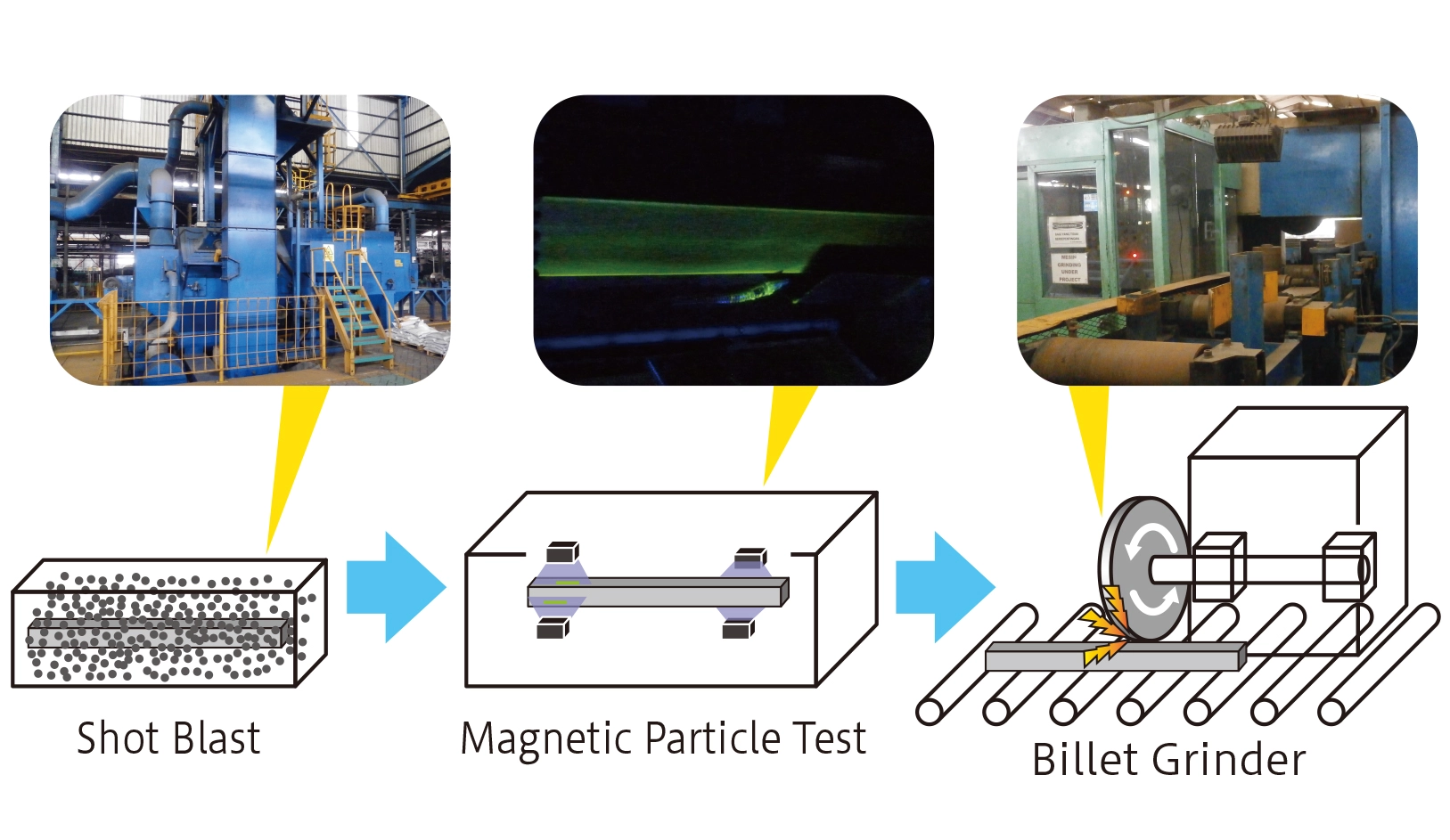

Billet Conditioning and Inspection Plant

- 1Prevention of defect outflow to the rolling process by implementing full inspection and maintenance of billets

- 2Complete removal of surface defects by billet grinder

- Finishing capacity:

13.5 thousand tons/month (billet amount)

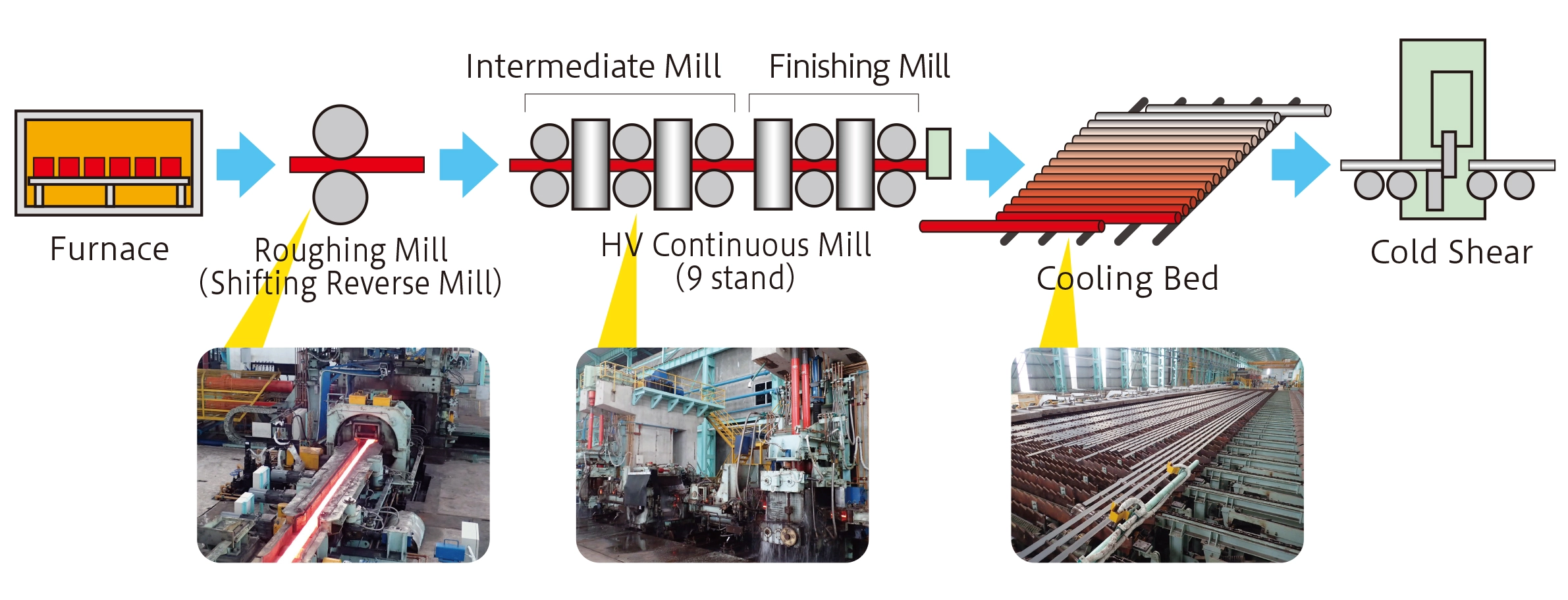

Rolling Mill

- 1Reduction of decarbonization and prevention of uneven heating by WB type heating furnace

- 2Reduction of temperature difference in top tail (uniform quality throughout the length) and reduction of conveyance defects by shifting reverse rolling machine

- 3Shortening of size change time by stand exchange device

- 4Automation of operation control by introduction of process management system

- Rolling capacity:

15.5 thousand tons/month (billet amount)

14.3 thousand tons/month (converted product amount)

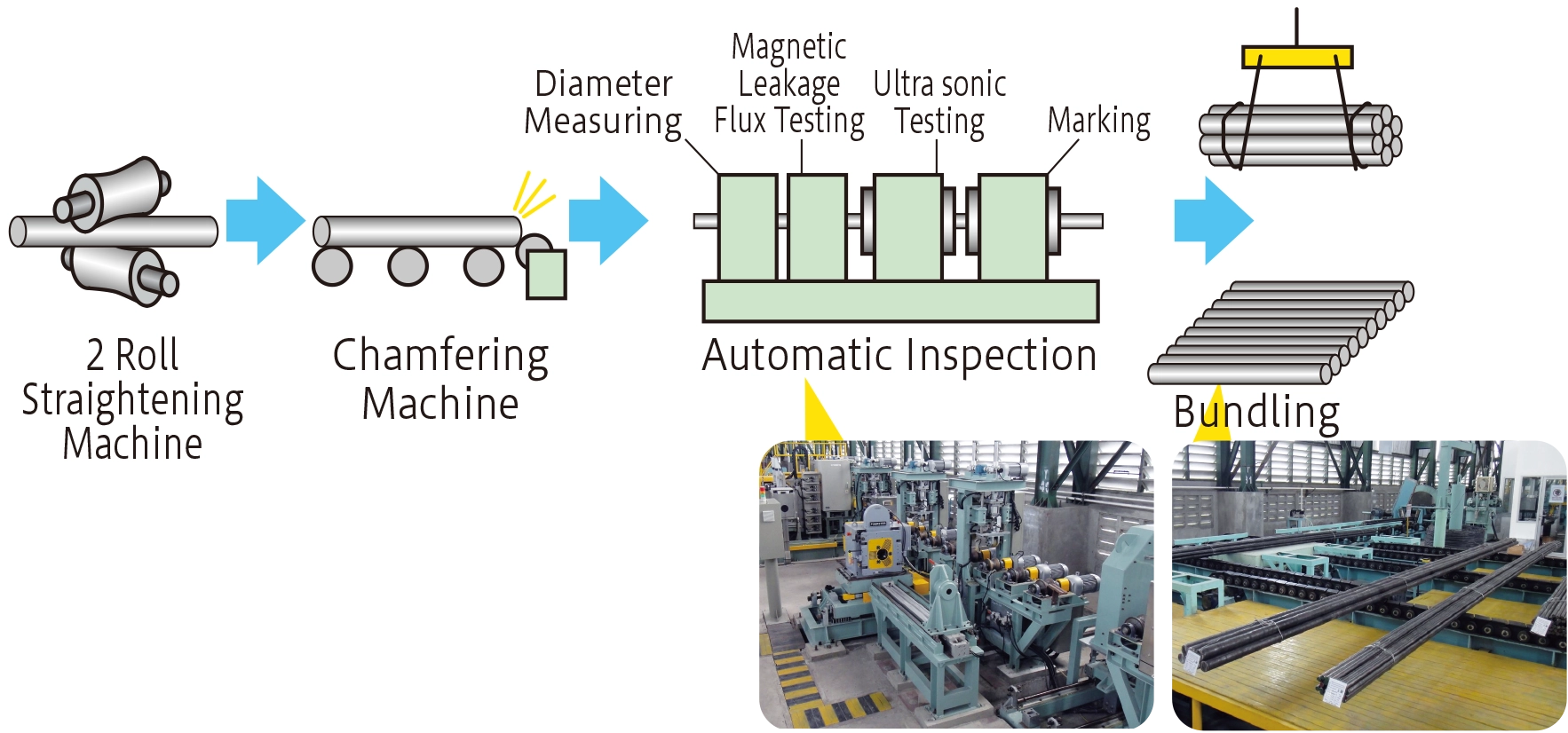

Round Bar Conditioning and Inspection Plant

- 1Full inspection conducted by automatic flaw detection equipment

- 2Prevention of surface defect leakage by introducing Foerster's magnetic leakage flaw detector

- 3Prevention of internal defect leakage by introducing Ryosho Electric's phased array ultrasonic flaw detector

- Finishing Capacity:

4.5 thousand tons/month (product amount)

(Capacity enhancement under consideration)

Contact for Special Steel Products

Steel Sales Department