Optimization of Gas-Atomized Powder Production Technology through Fluid Simulation

Products/R&D

2025/08/06

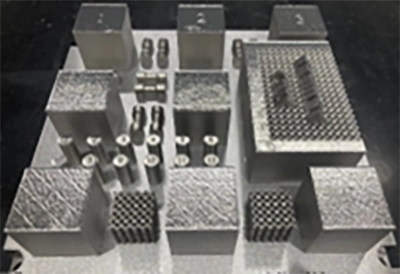

Our company is developing metal-powder manufacturing technology for additive manufacturing (metal 3D printing) by using a gas-atomizing system.

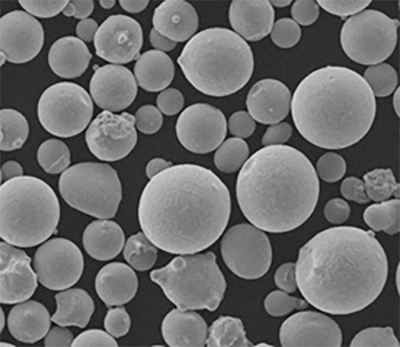

In gas atomization, molten metal (liquid steel) is discharged as a thin stream from a nozzle. A high-pressure stream of inert gas then impinges on the metal, breaking it up and atomizing it into fine droplets, which are rapidly cooled and solidified to form spherical metal powder. Although this method readily produces spherical particles, it has the drawback of making it difficult to generate very fine powder.

To overcome this challenge and supply high-quality powder for metal 3D printers at lower cost, we optimized the gas-spray parameters. By combining fluid-simulation analysis with in-situ observation on the production unit, we analyzed the pressure and velocity of the high-pressure spray gas and fed the results back into the process conditions. This enabled us to control both particle size and morphology, achieving powder optimization for additive manufacturing.

Building on this technology, we will further tailor particle-size distributions to meet diverse customer requirements and promote the production of specialty powders.

Contact Us

Research and Development Center