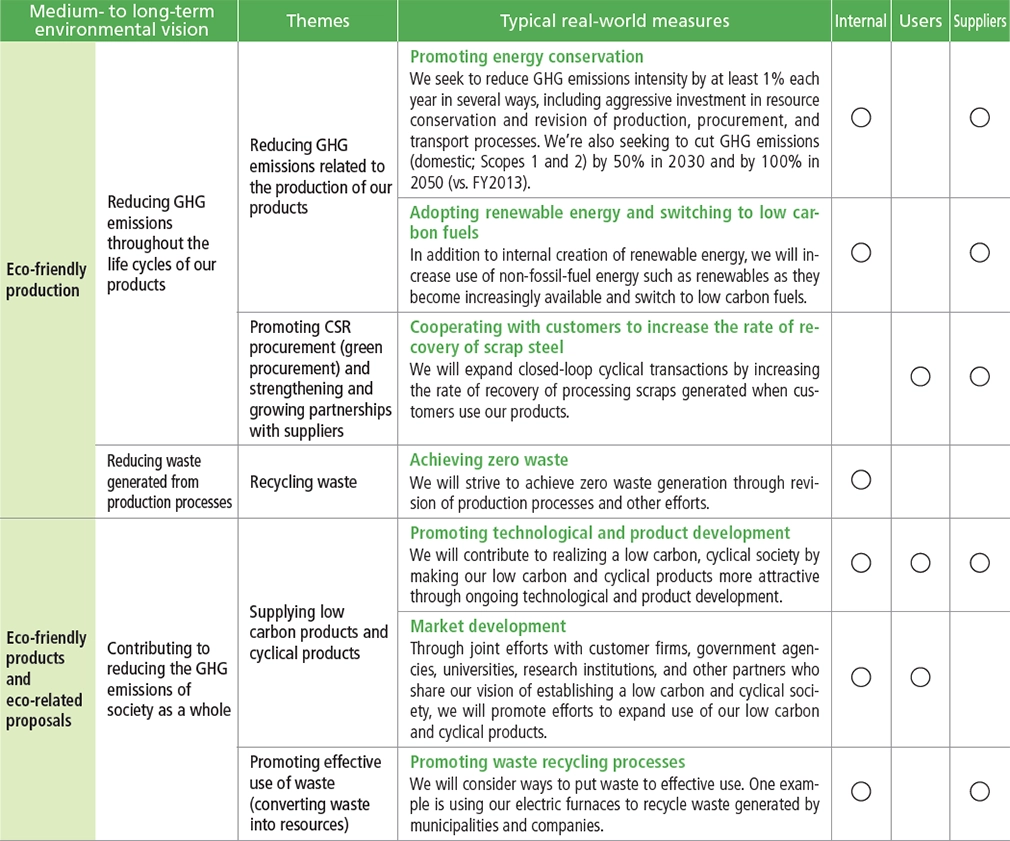

Carbon neutral initiatives

Medium- to long-term vision

The Mitsubishi Steel Group will take action toward its ideal vision for 2050 guided by the following medium- to long-term vision:

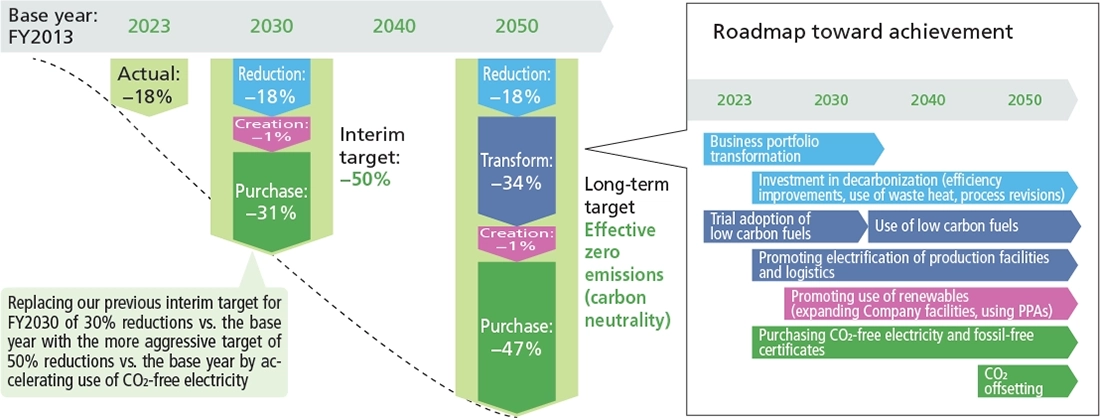

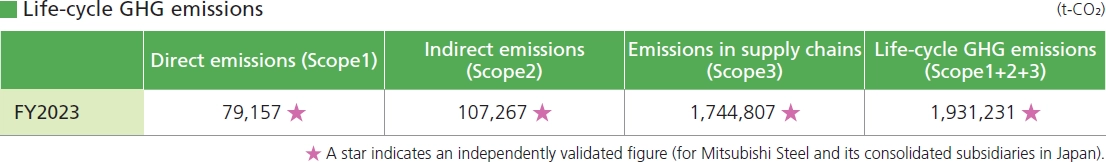

GHG emissions reduction

Scope 3 CO2 emissions by category(FY2023)

| Category | GHG emissions | % | Note |

|---|---|---|---|

| 1. Products and services purchased | 1,594,553 ★ | 91.4% | ― |

| 2. Capital goods | 10,498 ★ | 0.6% | ― |

| 3. Energy activities other than Scopes 1 and 2 | 14,449 ★ | 0.8% | ― |

| 4. Upstream transport | 32,376 ★ | 1.9% | ― |

| 5. Waste | 1,952 ★ | 0.1% | ― |

| 6.Business travel | 200 ★ | 0.0% | ― |

| 7. Commuting | 653 ★ | 0.0% | ― |

| 8. Leased assets (upstream) | ― | ― | not applicable |

| 9. Downstream transport | 18,359 ★ | 1.1% | ― |

| 10. Processing of sold products | 37,961 ★ | 2.2% | ― |

| 11. Use of sold products | 26,183 ★ | 1.5% | ― |

| 12. End-of-life treatment of sold products | 4,047 ★ | 0.2% | ― |

| 13. Downstream leased assets | ― | ― | not applicable |

| 14. Franchises | ― | ― | not applicable |

| 15. Investment | 3,576 ★ | 0.2% | ― |

| Total | 1,744,807 ★ | 100.0% |

Efforts toward achievement of targets

Since the second half of FY2022, we have promoted capital investments related to carbon neutrality by using ICP to reflect CO2-reduction effects as virtual prices in domestic businesses.

- Domestic carbon price: 10,000 yen/t-CO2

- Scope: Capital investments in domestic businesses

The Nomination and Compensation Committee and the Board of Directors decided to revise our executive compensation programs to incorporate nonfinancial indicators in the assessment indicators for bonuses and stock-based compensation in FY2023

and have started its adoption. Achieving these targets is reflected in payment amounts.

- We will promote the adoption of energy-saving technologies at each facility in accordance with each country's carbon neutrality targets.

- We will proceed with demand research and study the production of carbon neutral steel using electric furnaces in Indonesia (JATIM) as well as carbon neutral springs in the springs business.

- In Thailand (MSM THAILAND), we will continue to prepare for and study the introduction of renewable energy.

In February 2024, we joined the "GX League" in support of the "GX League Basic Concept," which aims to transform the entire economic and social system to simultaneously achieve corporate growth, consumer happiness, and contribution to the global environment, with a view to achieving carbon neutrality and social transformation in 2050. Going forward, we will promote efforts to reduce CO2 emissions and contribute to the realization of a carbon-neutral society. We will promote the introduction of energy-saving technologies to each of our bases in line with the carbon neutrality goals of each country.

The Group conducted third-party verification of its greenhouse gas (GHG) emissions data (Scope 1, 2, and 3) for fiscal 2023 (April 2023 to March 2024) in accordance with the international standard JIS Q 14064-3:2023 (ISO 14064-3:2019), and obtained an assurance report from the verification organization The assurance report was issued by SOCOTEC Certification Japan K.K., an organization that conducts such verifications. This has enabled us to disclose more reliable and transparent data to our stakeholders.

Scope of coverage

Mitsubishi Steel Mfg. Co., Ltd. and consolidated companies (4 subsidiaries in Japan)

Applicable period

April 1, 2023 - March 31, 2024

target item

Greenhouse gas (GHG) emissions from business activities (Scope 1, Scope 2, Scope 3 (Categories 1-7, 9-12, 15))

Efforts to lessen environmental impact

Switching to purchasing 100% CO2-free electricity (Chiba Works, Hirota Works)

The Chiba Works switched to purchasing 100% CO2-free electricity in April 2022. The Hirota Works also completed full switchover to CO2-free electricity in April 2023. This means that two of Mitsubishi Steel’s four main plants have switched completely to CO2-free electricity.

| Site | CO2Projected CO2 emissions (vs. before adoption of CO2-free electricity) | Time of adoption |

|---|---|---|

| Chiba Works | Reduced by approx. 8,300 t (approx. 50%) | April 2022 |

| Hirota Works | Reduced by approx. 7,600 t (approx. 90%) | March 2023 |

Energy conservation in tempering furnace conveyors for automotive coil springs (Chiba Works)

The Chiba Works has reduced the weight of the conveyor slats installed on the conveyors used in the tempering furnace process for automotive coil springs by switching to thinner, perforated slats. This has reduced the energy used in heating (which is sourced from city gas supplies). (The annual energy savings are equivalent to a reduction of approx. 560 t in CO2 emissions.)

Reducing CO2 emissions through use of hydrogen as an alternative cutting gas for cutting steel bars (Muroran Works) * A Challenge Zero Emissions project

LPG-gas cutting equipment is used to cut slabs cast in continuous casting equipment to appropriate lengths for final products. The Muroran Works aims to reduce CO2 emissions from this process to zero by switching from LPG to hydrogen.

The Muroran Works is working to replace LPG with hydrogen as the cutting gas used to cut slabs cast in continuous casting equipment through a series of steps from the testing and inspection stage through permanent equipment modifications.