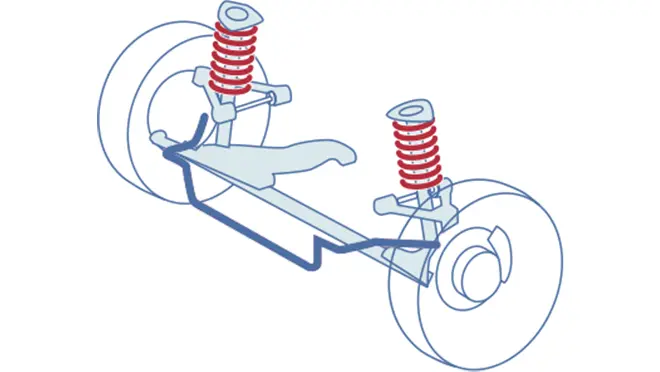

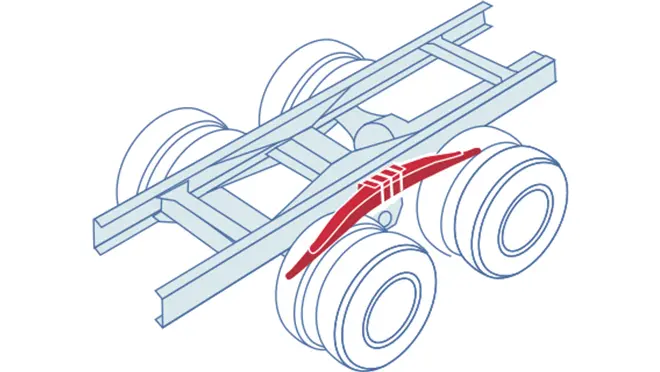

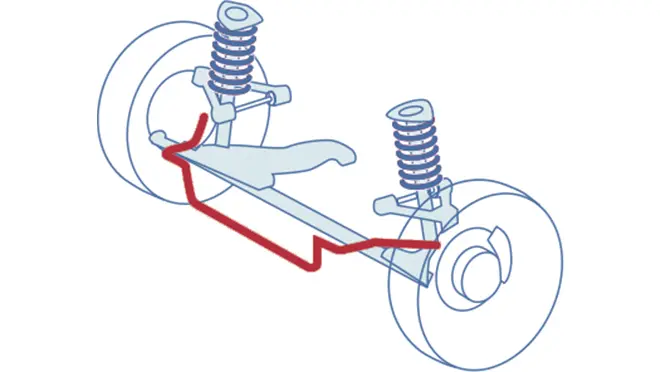

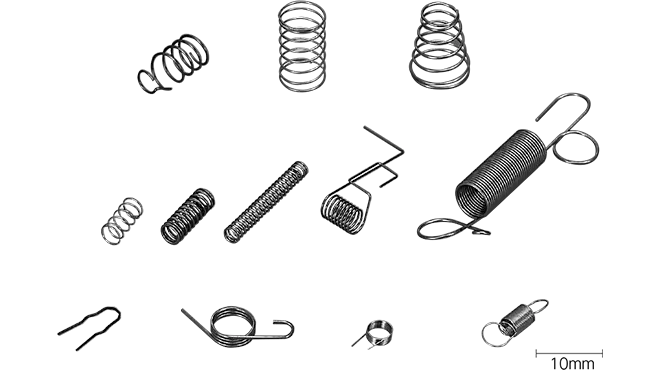

Spring Products

As the only spring manufacturer in Japan to boast an integrated production system covering everything from materials to products, we offer a wide-ranging product line ranging from precision springs to supersized springs.

We are the first in Japan to successfully manufacture springs in 1904, and have accumulated know-hows and experiences over a century. Our advanced technologies and strict quality control systems have created a highly efficient product that is trusted in a wide variety of fields.

We have applied our long time experience to a wide range of precision spring products, from single units to assemblies.

We respond to customer needs, actively provide technological support in design and analysis during the development phase. Our overseas locations are fully capable of accommodating local procurement needs.

Products

Contact for Spring Products

Spring Sales Department

Contact for Precision Parts

Functional Parts Sales Department