Special Steel Products

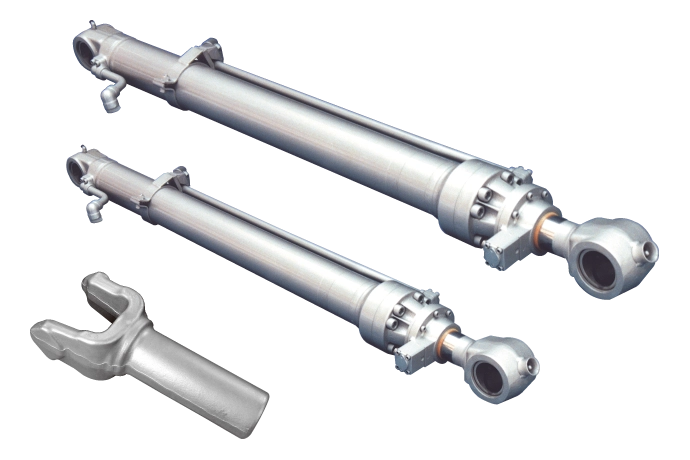

We produce special steels characterized by high strength and durability for use in construction machinery and other products critical to social infrastructure.

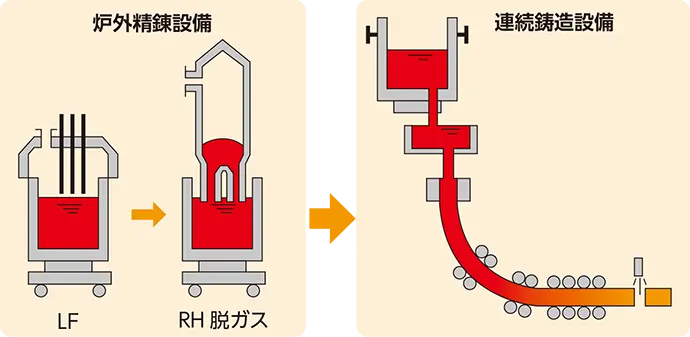

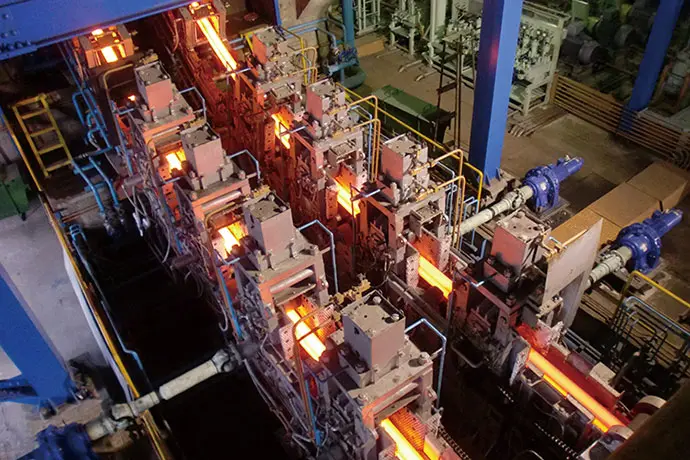

In Mitsubishi Steel Muroran Inc., there are two main plants, one is steel making plant which is utilizing both electric furnace and ladle furnace with out-of-furnace refining process and up-to-date bloom continuous caster, etc., and the other is rolling plant which has in-line high speed forging press providing a higher forging effect, and has V-H bar mill with high rigidity and automatic tension control. These equipment can produce special steel bars with low cost and high quality in a high productivity.

Our subsidiary in Indonesia, PT. JATIM TAMAN STEEL MFG., is the only special steel manufacturer in Southeast Asia, producing high-quality special steel round bars and flat steel from billets made by electric furnace method. In addition, we have obtained certification for JIS mark display (JIS G4051, G4052, G4053). We have also obtained certification (SNI8986:2021) for the SNI standard (Standard National Indonesia), which is the national standard of Indonesia for carbon steel for mechanical structures.

Product

Manufacturing Process

Contact for Special Steel Products

Steel Sales Department